While going through masonry projects the choice of bricks and brick supplier near me is the most crucial thought that an individual can think off. Fly-ash bricks are substitute of the residue that is emitted from thermal plant stations. In thermal plant station, the coal is burnt to produce heat energy and this heat energy is converted into electric power. The residue which is produced during combustion of coal comprises of fine particles that rise with the flue gases and it is called as fly-ash. Fly- ash contains trace amount of toxic metals such as mercury, arsenic, antimony, chromium, selenium, lead, cadmium, nickel, and zinc. These elements can put negative impact on human health, plants and land. When fly-ash settles on leaves and crops in agricultural field, it lowers the yield. On the other hand, when fly-ash gets decomposed in soil then that land becomes infertile. Fly-ash is a very fine powder and tends to travel in the air. If it is not properly disposed of, it pollutes air and water hence causing respiratory problems. Fly-ash is one of the numerous substances that causes air, water and soil pollution. Hence, it disrupts ecological cycle and set off environmental hazards. To overcome this problem many new uses of fly-ash have been found out through research. One such use is fly-ash bricks. By National Science Foundation in USA, it was concluded that fly-ash does not emit any mercury at all. On the contrary they absorb small amount of mercury from air in contact with bricks, making the ambient air slightly cleaner for people to breathe. Fly-ash bricks do not emit radon gas but only about 50% of that emitted from concrete. Thus if it is considered to use concrete it should be even safer to use fly-ash bricks. Leaching of pollutants from fly-ash bricks caused by rain is negligible. Fly-ash bricks are non- hazardous for land-filling or handling. While searching for best building material suppliers near me, it may be considered as good option to get thorough knowledge of these bricks. The best building material distributors or only Fly ash bricks suppliers can help to know advantages and utilisation of these bricks.

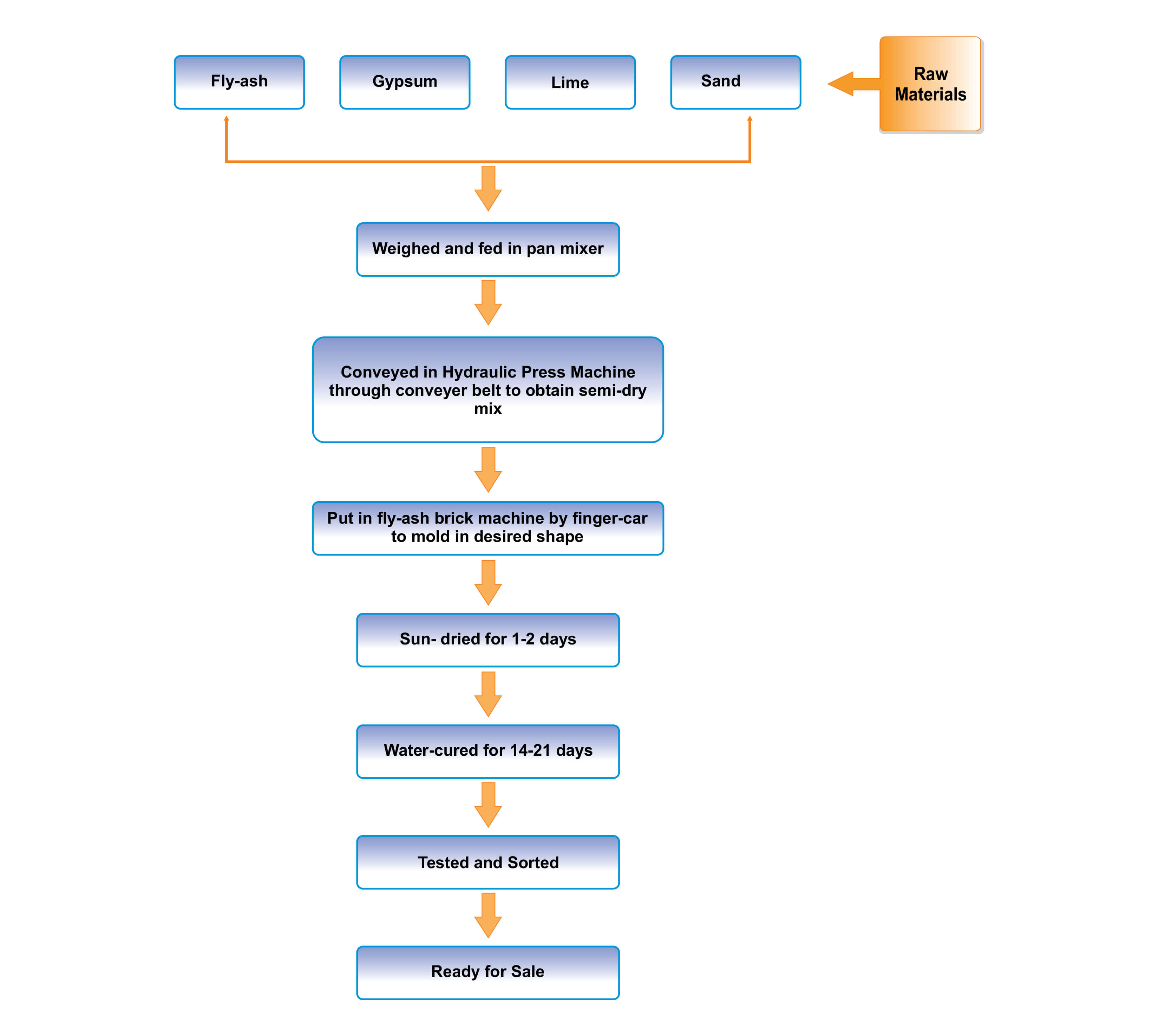

The raw materials used for manufacturing fly-ash bricks are fly-ash (50%-80%), sand/stone dust (20%-40%), cement/lime (5%-30%), gypsum (2%-15%), and water. The proportions of these raw materials can be changed depending upon the quality of raw material to produce different strength and density. All the raw materials are manually fed into a pan mixer where water is added in the required proportion for intimate mixing. OPC cement can also be used in place of hydrated lime and gypsum. After mixing all the raw materials in definite proportion, a semi-dry uniform mix is obtained which is further conveyed through belt conveyer to the hydraulic press machine. Here, the semi-dry mix is compacted and then fed in brick making machine which molds this mix into shape of bricks. After that, conveyer and elevator work to get those bricks from machine outlet to finger car. And then again with the help of finger car, the bricks are taken out. These bricks are dried up under sun from 24-48 hours. Molded bricks are air dried for one or two days in shade depending upon weather conditions and then water cured for 14-21 days. The bricks are tested and sorted before dispatch.

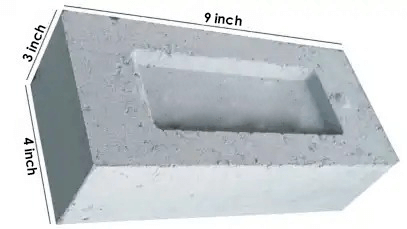

As per IS code the modular sizes of modular blocks shall be 190mm X 90mm X 90mm (7.4 in X 3.5 in X 3.5 in) or 190mm X 90mm X 40mm (7.4 in X 3.5 in X 1.5 in). On the other hand, non-modular sizes of fly-ash bricks shall be 230mm X 110mm X 70mm (9.0 in X 4.3 in X 2.7 in) or 230mm X 110mm X 30mm (7.4 in X 3.5 in X 1.2 in). But in market fly-ash bricks are available in different sizes like 9 in X 4 in X 3 in or 8 in X 4 in X 4 in etc.

| S. No. | Parameters | Fly-ash Bricks | Red Bricks |

|---|---|---|---|

| 1. | SHAPE | More uniform shape

(as they are casted in machine mold) |

More uniform shape

(as they are casted in hand mold made) |

| 2. | COLOR | Grey | Red to brown color depending on type of clay |

| 3. | WASTAGE DURING TRANSIT | Around 2-5% | More than 10% |

| 4. | WEIGHT COMPARISON | 1 Fly-ash Brick = Approx.2.6 Kg | 1 Red Brick = Approx. 3.5 Kg |

| 5. | THERMAL CONDUCTIVITY | 0.3-0.4 W/mk

(Less heat transfer) |

0.6-1.0 W/mk

(More heat transfer) |

| 6. | DRY DENSITY |

1700-1850 kg/ m3

(Less dead load on structure) |

1600-1920 kg/ m3

(More dead load on structure) |

| 7. | COMPRESSIVE STRENGTH |

75-100 kg/cm2

(More strong) |

30-35 kg/cm2

(Less strong) |

| 8. | WATER ABSORPTION RATIO | It should not be more than 6-12%. | It should not be more than 20-25%. |

| 9. | TERMITE RESISTANCE | Resitant

(Because it is made up of inorganic material) |

Not resitant (Because it is made up of organic material) |